In-situ extraction

In-situ retorting technique/Radio frequency heating

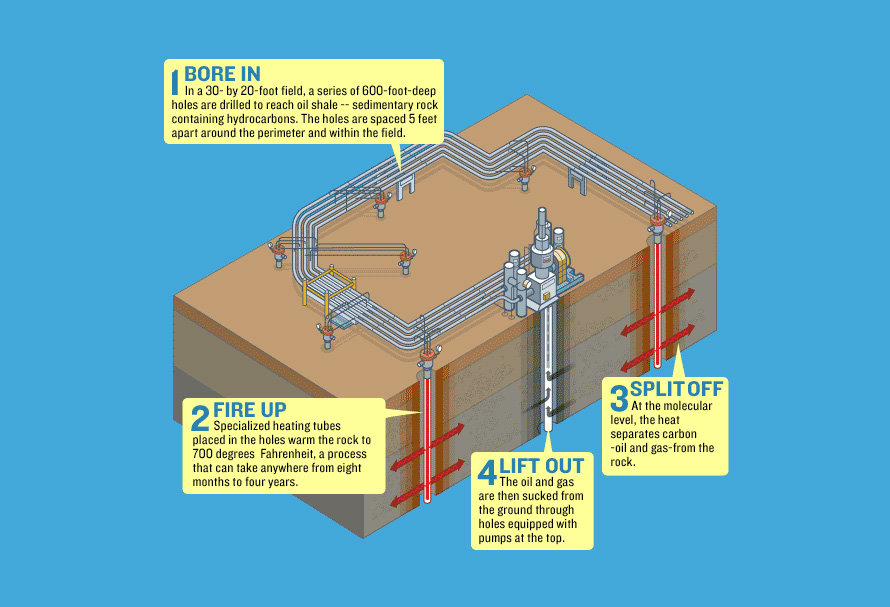

The technology will accelerate the natural process of kerogen processing by slowly heating shale underground.

As a result:

- Thermal decomposition;

- Oil will be enriched by hydrogen underground;

- Will create high flow gas condensate;

- Extraction of high grade API petroleum;

- Depends on the reserve of Nitrogen, sulfur, oxygen

Average heating temperature is the boiling temperature of diesel fuel.

How to achieve:

Will use electricity or gas heater;

Will use special technology to transfer heat underground

In-situ Hydraulic Fracturing

Hydraulic fracturing is a procedure that can increase the flow of oil or gas from a well. It is done by pumping liquids down a well into subsurface rock units under pressures that are high enough to fracture the rock. The goal is to create a network of interconnected fractures that will serve as pore spaces for the movement of oil and natural gas to the well bore.

Hydraulic fracturing combined with horizontal drilling has turned previously unproductive organic-rich shales into the largest natural gas fields in the world.

When the water is pumped into the well, the entire length of the well is not pressurized. Instead, plugs are inserted to isolate the portion of well where the fractures are desired. Only this section of the well receives the full force of pumping. As pressure builds up in this portion of the well, water opens fractures, and the driving pressure extends the fractures deep into the rock unit. When pumping stops these fractures quickly snap closed, and the water used to open them is pushed back into the borehole, back up the well and is collected at the surface. The water returned to the surface is a mixture of the water injected and pore water that has been trapped in the rock unit for millions of years. The pore water is usually a brine with significant amounts of dissolved solids.